Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

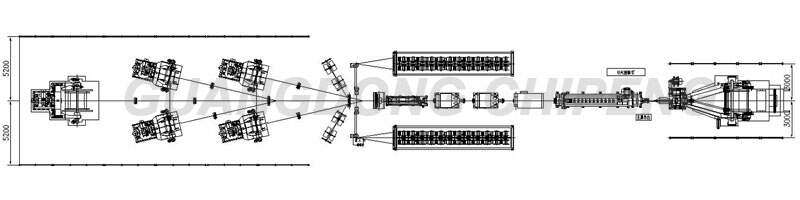

3150/4 drum twister machine

The 3150/4 Drum Twister Machine is an advanced solution designed for the lay-up and armoring of large-section, long-length power cables. It supports a wide range of materials, including copper tape, steel wire, and non-metallic shielding layers. With its high-speed performance, intelligent PLC control system, and modular design, this machine delivers excellent production efficiency, precision, and ease of maintenance—ideal for modern cable manufacturing lines.

Product Features

Full PLC Control System for Automation and Safety

The line is controlled by a high-performance PLC system that manages the regulation, synchronization, and operation of motors. Operators can monitor process parameters in real-time, store multiple production recipes, and quickly identify faults via the touch screen display.

Flexible and Precise Cable Pitch Control

The machine allows online adjustment of cable pitch, directional wiring (left/right), jogging, and fast-speed movement—all accessible and editable through a user-friendly touch screen interface.

Modular Drive Systems with Reliable Motor Configurations

Each key function—including pay-off, twisting, wrapping, traction, and take-up—is powered by AC variable frequency motors with speed controlled via inverters. The take-up unit uses a high-performance DC motor supported by an SSD Parker 590 series DC drive for enhanced reliability.

Advanced Safety and Protection Systems

Equipped with comprehensive safety features such as horizontal fork protection, hydraulic lift reset protection, air pressure undervoltage protection, broken tape alarms, and travel switch limits, ensuring safe and stable production.

Optimized Drum Twisting Structure for Noise Reduction and Efficiency

Utilizes the latest drum twisting architecture, offering high rotational balance, low noise, high strength, and smooth operation. The back twist rate is freely adjustable between 0–100% to suit varying cable structures.

Technical Specifications

|

|

Single Wire Diameter |

Max Pay-off Speed |

Max Line Speed |

Max Caterpillar Force |

|

3600 |

Φ25–Φ130 mm |

21 r/min |

33 m/min |

4000 kg |

|

3150 |

Φ25–Φ120 mm |

33 r/min |

50 m/min |

4000 kg |

|

2600 |

Φ25–Φ100 mm |

33 r/min |

50 m/min |

- |

Supporting Components

Center & Rotating Pay-Off Units:

Fork-type cantilever design

Pneumatic tension control and shaft-less bobbin clamping

Manual and synchronous motor-driven operation

Crane-assisted bobbin loading

Pneumatic braking system

Double-Disc Non-Metallic Taping Head:

Supports polyester, non-woven, glass cloth, copper tape, etc.

Left/right rotation, mechanical tension feedback, and parking detection

Steel Tape Armoring Head:

AC motor drive with mechanical friction control

Designed for accurate, stable steel taping under dynamic conditions

6T Rotating Caterpillar:

6000 kg max force, 50 m/min max line speed

Powered by a 37KW AC variable frequency motor

Smooth, high-torque performance for heavy-duty operations

Rotating Take-Up Unit:

Shaft-less clamping, DC motor drive with 250 kg max tension

AC traverse with auto-switching pitch control

Touch screen interface for direction, inching, and speed setting

Hydraulic lifting for easy bobbin handling

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost